Our Service

OZONE IN AGRICULTURE

Ozonated water used for Irrigation provides oxygen to the root making it free of virus, bacteria, fungi, seaweed, spores and any other microorganisms, and further promotes fast and steady growth, with more aliveness as well as more productivity.Ozone improves the respiratory process at cellular level. The direct germicidal action of ozone is well-known against all types of microorganisms, such as fungi, bacteria and virus. Ozone fight against bacteria such as: pseudomonas, Flavobacterium, streptococcus, Legionella, etc. In the particular cases of fungi and bacteria which are the main cause of degradation of vegetables. Ozone is very effective against these microorganisms which are able to propagate and reproduce in harsh and extreme conditions also.

It is known that the spores mentioned are very resistant when the conditions are adverse for them and can remain for a long time in latency, being transferred from one place to another through air or other ways, until they again find propitious condition for growing, in this case it is extremely difficult to eradicate such infection using other alternates and is such cases ozone proves to be very effective and provides complete protection.Ozone is a very powerful germicidal agent, which is able to eliminate parasitic bacteria's, virus, fungi and cysts, without forming toxic compounds or leaving harmful residues behind, since it decomposes back to oxygen. Ozone is extremely useful for irrigating fruit trees, vineyards and cultures in preventing them from deadly diseases.

Protects Against Diseases

Most of the diseases of the plants take place due to infection. Ozone destroys all the microorganisms present in water as well as increases the oxygen content. Irrigation using Ozonated water also protects against contagious diseases, destroys bacteria, virus and parasitic cysts, which are difficult to fight using other alternative methods. Use of pesticides and other chemical agents leave behind residues, which are harmful for human consumption and for the environment as well on the other hand ozone does not leave behind any residue and decomposes back to oxygen.

Moreover, any product irrigated with ozonised water, stored and transported in ozonized atmosphere, conserves all its characteristics for a much longer time.

Promotes Better Growth

Irrigation using Ozonated water consist greater amount of Oxygen content as ozone decomposes back to Oxygen once it comes in contact with impurities present in the water. The ozonised water that is used for irrigation is free from viruses, bacteria, fungi, seaweed, spores and any other microorganisms. Water in the absence of germs confers to the best conditions possible to obtain faster growth, the plant grows with more aliveness, more vitality and force and it will be able to grow within a very short duration of time (between 30 to 40 days from the beginning).

Provides More Benefit

Irrigation using Ozonated water provides a more voluminous and productive harvest which is obtained in a very short duration of time, implying a huge saving in amount of water used for irrigation and the cost for fertilizer and additives which are further used to promote faster growth. The use of fertilizer and additives is reduced to almost 50%, when Ozonated water is used for irrigation purpose, due to which the cycle of maturation of crops is completed within a very short duration of time and represents the same size, strength and volume which are gained using fertilizers and additives.

Improves Taste And Flavour

- Use of Ozonated water for irrigation increases the taste and flavor of the harvest.

OZONE IN AQUACULTURE (FISH FARMING)

Ozonation Systems are widely used in aquaculture for water conditioning that improves the health of marine animals.Conventional means of solids removal, such as sponge/ perlon floss filters and sand filters address the removal of coarse settleable and filterable solids, but not the removal of fine colloidal solids. Similarly, nitrifying bacteria in bio-filters remove dissolved ammonia and nitrite, but not all dissolved organic wastes. As an aquarium matures, the accumulation of dissolved organic colloidal solids increases. This organic buildup decreases the performance of the nitrifying bacteria that convert nitrite to nitrate, thus causing harming nitrite buildup. The biochemical oxygen demand also rises, so the oxygen levels decrease over time. These shifts in water parameters stress the aquarium inhabitants and may even cause mortality. To reduce the necessity of large water changes, that can change the systems chemical parameters (PH, salinity, alkalinity etc.), there is a very efficient alternative method of breaking down these organic wastes using a strong oxidizing agent Ozone.Ozonized water is widely employed at aquariums, sea parks and zoos, where it safely removes disease causing microbes or fungus without using harsh and increasingly regulated chemicals that may form harmful byproducts.

Removal Of Fine And Colloidal Solids

A fine and colloidal solids consist of particles 1-30 microns (mm) and 0.001 (mm) respectively. The small size of the particles enables the solids to remain in suspension and avoid most mechanical methods of separation. The accumulation of fine and colloidal solids can impair bio-filter nitrification efficiencies and stress fish stocks Ozone removes fine and colloidal solids by causing clumping of the solids (microflocculation), which facilitates removal by foam-fractionation, filtration and sedimentation.

Removal Of Dissolved Organic Compounds

Dissolved organic compounds or refractory organics, give the water a characteristic tea-colored stain. Dissolved organic compounds are non-biodegradable and accumulate according to feed input, water exchange rate and the rate of solids removal. High levels of Dissolved organic compounds can stress fish and reduce nitrification efficiencies of the bio-filter. Ozone removes dissolved organic compounds by : Oxidation into products that are more readily nitrified.

Removal Of Nitrite

Nitrite can accumulate as production intensifies and organic loadings increase. Bacteria that process ammonia into nitrite (Nitrosomonas spp) operates more efficiently under high organic loadings than bacteria that process nitrite to nitrate (Nitrobacter) and levels of nitrite rise accordingly. High levels of nitrite can be toxic to fish. Data available for silver perch, bidyanus bidyanus indicates levels of nitrite as low as 2.8 parts per million (ppm) can reduce growth of fingerlings by 5%.

Disinfection

The high stocking densities, associated fish stress and increased nutrient loads found in RAS create an ideal environment for fish pathogens. An important step in reducing the risk of disease outbreaks in RAS is the use of standard quarantine procedures for any fish introduced. Facilities using surface waters, including RAS and flow through hatchery systems, are also interested in reducing the pathogens load introduced via the source of water. The disinfection of effluent waters introduction to the environment is also crucial to prevent the translocation of exotic diseases. Ozone can effectively inactivate a range of bacterial, viral, fungal and protozoan fish pathogens. The effectiveness of Ozone treatment depends on ozone concentration, length of ozone exposure (contact time), pathogen loads and levels of organic matter. If high levels of organic matter are present, the demand created by oxidizing the organic matter can make it difficult to maintain enough residual ozone for effective disinfection.

OZONE IN DRINKING WATER

When ozone is applied, as a gas, for drinking water treatment, it is done primarily because of its excellent oxidative strength. This powerful oxidation potential allows ozone to be effective in the reduction or elimination of color, after taste and odor, all of which may be fundamental problems associated with a

specific water supply. More importantly, ozone will effectively destroy bacteria and inactivate viruses more rapidly than any other disinfectant chemical. Ozone is also very effective in oxidizing heavy metals. Iron and manganese can be reduced to very low, safe levels in water supplies through ozone oxidation. When properly applied at the start of a water treatment process, ozone will not lead to the formation of halogenated compounds such as Trihalomethanes (THM's) which are formed when chlorine is added to the raw water.

The Main Effects of Ozonisation of Drinking Water

Iron and Manganese Removal : - The standard oxidation-reduction potential and reaction rate of ozone is such that it can readily oxidize iron and manganese present in the raw water and in water with low organic content.While Iron and Manganese don't pose health problems, but water contaminated by iron and manganese can stain water fixtures and clothing that is washed with this water. Chlorine can also be used for oxidation of iron and manganese, but significantly more chlorine is required versus ozone. This is due to the fact that ozone has an oxidation potential 150 times greater than chlorine. The use of chlorine can also result in the formation of THM's if organic material is present in the water.

Ozone oxidizes Iron from Fe (II) to Fe (III). Fe (III) hydrolyzes to Fe (OH3) which precipitates to a solid form which can be filtered. The oxidation reaction requires 0.43 mg of ozone per mg of Fe (II). Excess ozone can be used without negative effect. Fe oxidizes in the pH range of 6-9. Ozone oxidizes Mn (II) to MnO2 (Mn IV) which is insoluble and can be filtered out of water. The oxidation reaction requires 0.88 mg of ozone per mg of Mn (II). Excess ozone beyond this ratio will form soluble Mn (VII), permanganate. If oxidizable organic material is present in the water and there is sufficient contact time, permanganate will be reduced back to MnO2 (Mn IV). Manganese oxidation is most effective around a pH of 8. In general, when organic materials are present in water, more ozone will be required than the amount shown above since ozone will also oxidize these materials.

OZONE IN COOLING TOWERS.

Ozone is widely used in Cooling Towers to improve cooling water quality. As an alternative to conventional biocide chemicals, ozone represents a more effective and environmentally friendly solution. Cooling systems provide ideal growth environments for bacteria, algae, fungi and mollusks which can adhere to pipeline, heat exchanger and cooling tower surfaces. The result can be reduced heat transfer efficiency, increased corrosion and potential system failure. Biological growth, scaling and corrosion are the main maintenance concerns with cooling towers. Typical treatment involves the application of chemicals such as chlorine, sulfuric acid, phosphorus and zinc compounds. Care must be taken in the storage, use or discharge of these chemicals. Care must also be taken to ensure that the proper mixes and proportion of chemicals are used and to determine the corresponding blow down rates. Excessive application of these treatment compounds raises the probability of corrosion and other undesirable effects. As traditional chemical water treatments are being restricted because of environmental concerns, Ozone is gaining acceptance as a viable biocide alternatives.

Ozone produces oxidation by-products and these several secondary compounds must be accounted for in the set up of cooling tower system Ozonation. Both iron and manganese will be oxidized by the ozone to form insoluble particulate matter, which will collect in basins on screens or in any scale that is formed. Excessive amounts of either of these two elements in the make-up water will require pretreatment, such as softening, to facilitate removal. Organic compounds that may either be in the make-up water or introduced through the atmosphere will react with ozone to form various substances. These substances, particularly peroxides, aldehydes, ketones and alcohols are efficient biocides themselves, which will further disinfect the water. If bromide is present, ozone can convert it to hypobromous acid and hypobromite ion. These two are also effective biocides and would be considered helpful in controlling biological fouling, but because they are such effective biocides, they are generally detrimental in the blowdown discharge to municipal waste water treatment systems. Excessive ozone concentrations in the water will further oxidize the hypobromite ion to bromated, reducing the biocidal effectiveness of this component.

Effect of Ozone on Biofilms

On heat exchanger surfaces, biofilms degrade heat transfer efficiency, increase pressure drop (and pumping power required) through exchanger tubes and plates by substantially reducing flow rates through these machines and can lead to corrosion problems under the film. Ozone kills organisms by rupturing their cell walls, a process to which the microorganisms cannot develop immunity. When oxidized, the mucilaginous material secreted by these microorganisms is loosened from the heat exchanger surfaces, and the biofilms, along with inorganic precipitates which were adhered to the secretions, are flushed away by the motion of the flowing water. Once biofilms have been removed, ozone concentrations of less than 0.1 mg/lit have proven to be effective in preventing new growth of bio-fouling material.

Effect of Ozone on Algae

Most algal species are readily oxidized upon application of ozone; different species will require different exposure times for removal. The oxidation pocess can proceed to total decomposition of the algae to carbon-dioxide and water with sufficient concentrations of ozone and contact time. A combination of controlled sunlight exposure and low level of residual ozone will minimize algae growth in the cooling tower fill and basin. Destruction of many algal species using ozonation will liberate nucleic acids, proteins, polysaccarides, and other bio-polymers. The production of polysaccarides by exposure of biofilms and algae to ozone liberatessurface active materials with ability to complex iron, manganese and calcim effectively removing them from solution in the tower water and thereby reducing scaling potencial. These surface active substances, through micro-flocculation, may contribute to the observation that ozone treated cooling tower water becomes crystal clear.Ozone treatment is a unique and valuable process. It can accomplish all the aforementioned treatment objectives without leaving a taste or chemical residue behind. Ozone is an exceptionally powerful disinfectant and oxidant. It does its job and disappears. With appropriate pretreatment and careful monitoring and control, it can leave water free of disinfection by- products as well.

OZONE IN AIR DISINFECTION

Like the water we drink and the food we eat, the air we breathe has a great impact on our health. There are some contaminates in the air such as bacteria, virus, germs, airborne pathogens and disagreeable odor, such as formaldehyde, smoke, paint, cooking smell. These can cause various diseases such as asthma, irritative odor and respiratory problems. The best and effective solution is to use ozone for Air Disinfection. Since Ozone is a powerful oxidizer it eliminates any kind of bacteria, virus, germs, airborne pathogens and other contaminants present in the air. Brief description of Ozone Application areas and recommendations for Air Disinfection using Ozone:

Air Conditioning

The collection of particulate organic material and condensation of moisture that occurs around the drip pans, condensation coils and duct work of air conditioning units creates the perfect environment for the growth of bio films. Not only do these lead to high levels of fungi and bacteria that become airborne and get transported around the building via air recirculation, but they also reduce the efficiency and heat transfer of the systems. Airborne bacteria and fungi do not only present a major health hazard but also bad smell. By treating the air conditioning system with ozone, you can prevent the build-up of bio films, and consequently the build-up of bacteria and fungi. This will eliminate bad smell and the spread of health problems such as allergies, rashes, colds, viruses and legionnaires disease

Food Storage

Due to ozone's potency as an oxidant, use in food storage is a perfect application area. It can be utilized as a gaseous fumigant within a number of phases of food storage, including storage rooms, coolers, silos, and transport vehicles, fulfilling a number of functions in each stage. Two of the main areas in which ozone can be most fruitfully utilized are within the pre-packing stage of production for products such as meat and poultry, and the storage of directly harvested products, such as potatoes. Ozone treatment of products prior to packing dramatically reduces bacteria levels, as well as controlling Listeria and other pathogens, helping to extend the shelf life of the products. As well as the products being treated, the equipment that is used in the production process can be treated at the same time, thus increasing the efficiency of the process. Ozone treatment is also safe for ready-to-eat products as well as those that require further preparation. With the storage of harvested products, such as potatoes, ozone treatment implies that the problem of products rotting is greatly reduced due to ozone's ability to eliminate the harmful bacteria, such as Erwinia in the case of potatoes that cause the rot.

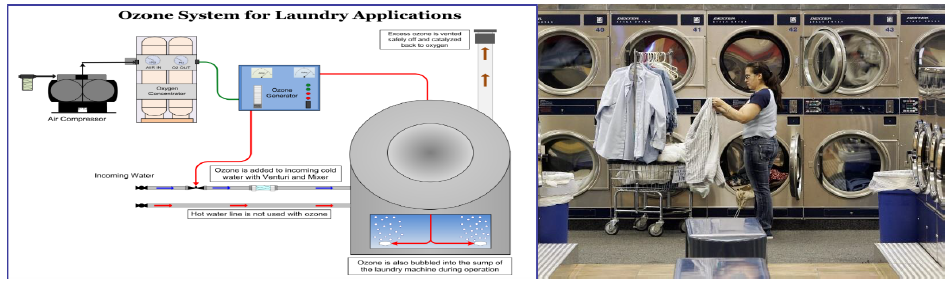

OZONE IN LAUNDRY

Energy efficiency is not usually associated with laundering the many different types of linen that pass through health care facilities. Hygienically clean linens are a necessity, and the traditional means of getting them clean involves many chemicals, hot water, and high sewage costs. However, ozone laundering, a relatively new method used in all major upcoming countries, is changing the perception of laundry as a non energy-efficient necessary evil. The concept of washing clothes with the aid of ozone (O3) gas dissolved in ambient temperature water was first introduced to the American laundry industry in 1991. The system touted the capability of reducing energy use and traditional wash chemicals while recycling most of the wash water for reuse. Since that time, the number of laundries embracing this technology has grown dramatically. Ozone occurs in nature as a result of electrical discharge (for example, lightning), ultraviolet radiation, or the photochemical action of sunlight on atmospheric oxygen. European scientists learned how to recreate these reactions in controlled laboratory experiments in the latter part of the 19th century and by the turn of the century the first ozone generators were being produced commercially in France and Germany. Ozone is a colorless gas that in low concentrations has a slight odor, most often described as the smell of fresh air after a thunderstorm. Extremely unstable, ozone cannot be stored and must be generated on site. It is one and a half times as dense as oxygen and about 13 times more soluble in water. Ozone to be second only to fluorine in its oxidizing potential and 150% more powerful in its disinfecting capabilities than chlorine. In an aqueous solution, it is an effective biocide, capable of destroying bacterial and viral colonies. It is also effective against molds and fungi and as a deodorizer of air and water. Ozone works well as a disinfectant because upon disintegration it reverts to its original form, oxygen (O2). It dissipates quickly in water temperatures more than 38ºC (104ºF), which mandates the use of lukewarm water. Ozone has been utilized for more than 100 years in Europe in positive applications as diverse as primary disinfection of municipal drinking water supplies, aquaculture, and pulp bleaching. Its widespread use in the United States has been hampered by the preference for inexpensive chemicals (especially chlorine) compared with the expensive, generally unreliable ozone-generating equipment. But with mounting federal government pressure to reduce chemical pollution of the environment, coupled with the development of cost-efficient, reliable, and low-maintenance ozone-generating systems, these systems are gaining popularity. The main benefits of Laundering with ozone are as follows:

Cost Saving Advantages

Conventional washing methods require that 70% of wash water be heated to temperatures in ranges of 60º to 82ºC (140º to 180ºF) for proper stain removal when used in conjunction with conventional chemicals. With the ozone washing system, no water is heated to more than 32ºC to 35ºC (90ºF to 95ºF), and then only in heavily soiled wash loads.

Chemical Cost Reduction (60% - 65%)

Ozone enhances the power of detergents by breaking water surface tension and nullifying the water-hardening effects of Calcium and Magnesium. Ozone makes water soft without the use of traditional water softening equipment. Your laundry detergent will go a lot farther. When you first switch to a Water Energy Ozone Standard, unless you have brand new linens, you will have suds whether or not you add any soap for the next 4 or 5 times you wash them. There is so much residual soap and chemicals that you will be amazed at how many suds you get without adding any soap! This should clearly illustrate just how much soap remains in your linens with traditional laundering methods. Switch to ozone and greatly reduce the amount of chemicals needed to provide superior results. Stop all those chemicals from getting on your guests or patients. The linens smell and feel like new instead of having that 'odd' smell and scratchy feel characteristic of towels in a hotel or hospital.

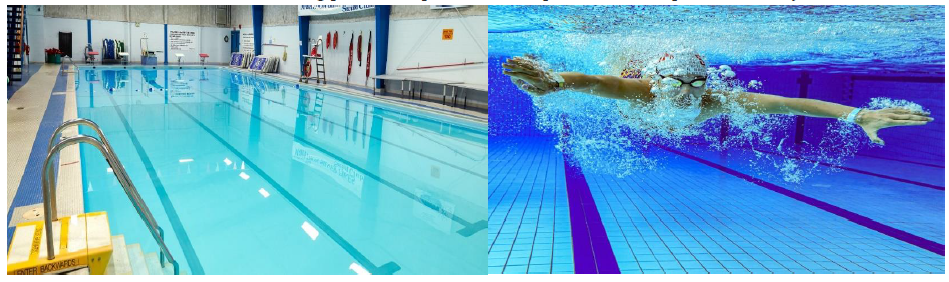

OZONE IN SWIMMING POOLS

than 500 Ozone treated pools, the European Community (EC) now considers Ozone treatment a standard method of pool disinfection. Some countries require mandatory compliance with the German Din. 19643, a comprehensive codes standard that covers all aspects of pool design and water quality including the use of Ozone for disinfection. Other countries, such as England, have established their own standards concerning the treatment of pool water. The British Effluent and Water Association (BEWA), for example, has established a "Code of Practice" that details the design and use of Ozone water treatment systems for swimming pools. California and Oregon provide guidelines on the treatment of swimming pools with Ozone. Currently, however, there is no comprehensive standard on the design and use of ozone in swimming pools within the U.S.

Reduced Chemical Usage

When ozone is properly applied it can demonstrate chemical savings in two ways. First, if ozone is sized and integrated into the treatment system properly, it will act as the primary oxidizer and disinfectant. This reduces the amount of chemical (chlorine or bromine) needed to maintain the free halogen residual required by state law. Second, when ozone is used in conjunction with sodium bromide, it has the potential to regenerate spent bromine, thus reducing the sodium bromide feed rate. Some facilities that use ozone and sodium bromide in this manner have reported up to a 60 percent reduction in chemical usage.

Superior Disinfection

Ozone has been shown to be a superior disinfectant to chlorine or chlorine-bromine treatments still used in many U.S. pools and spas. Studies conducted under the guidance of Dr. Eugene Rice. USEPA Office of Drinking Water Standards, show that the C.T value [(Disinfectant concentration in mg/L) X (Contact time of disinfectant with water)] of free chlorine for 99 percent inactivation of the Cryptosporidium oocyst is 7,200, while ozone shows a much lower C.T value of 5-10. Ozone's reaction against fecal coliforms is even more dramatic. Strains of E. Coli bacteria exposed to a 0.1 mg/L residual of ozone are destroyed in less than 12 seconds.

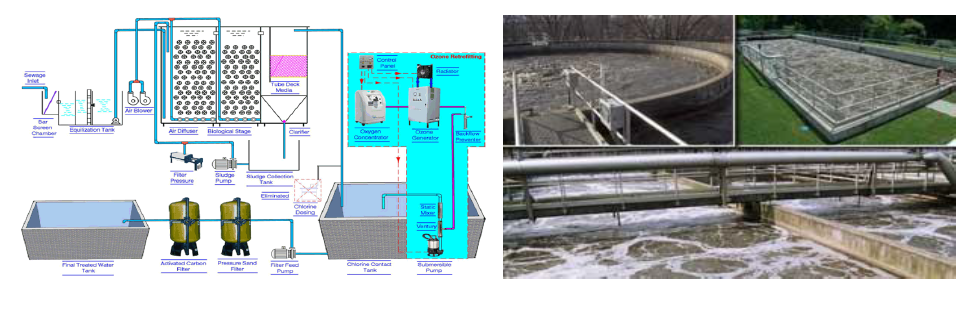

OZONE IN WASTEWATER

Environmentalists and water treatment experts are predicting that the recycling of wastewater will be a norm in the coming years. This makes one wonder that how the recycling can be done on the wastewater, which at present cannot be treated to the satisfaction of pollution control board. We spent crores of rupees every year to treat the effluent and we throw away the entire treated water. The problem with the wastewater are typically in the areas of COD, BOD, DOC, color removal and toxic chemicals removal from the wastewater and the systems we have that take care of these problems are huge. They take up a lot of your valuable land and other scarce resources. They require regular maintenance and consume a lot of chemicals daily. The chemicals add to newer problems. Ultimately there is no guarantee that your system is a full proof system.

Ozone reacts very aggressively with cyanide (CN). Cyanide is frequently used in galvanic processes in the metal processing and electronic industries. Nitrite (NO2) as well as sulfide (H2S/S2) removal from the effluent is easier using ozone as both substances react aggressively with ozone. Nitrite is a toxic compound. Fe2+ and Mn2+ compounds are rapidly converted into filterable Fe (OH)3 and MnO (OH)2 due to ozone. The application is in the beverage industry. Arsenic removal system also utilizes ozone for pre-oxidation, as As-III is converted to As-V. Oxidation of organic compounds: Full scale ozonation systems have been used to treat effluent such as landfill leachates as well as effluent from the textiles, pharmaceutical and chemical industries. The main pollutants associated with these waters are refractory organics, which can be characterized as :

Water appears colored when visible radiation is absorbed by dissolved materials or when light is reflected by suspended solids. Colored water is basically found at dye houses, textile concerns, food and beverage processors, slaughter houses and other industrial plants. Many industries have already started using ozone, which is a more powerful and a safer substitute than chlorine for color removal. The best results are achieved when water has been treated to lower BOD, COD and suspended solids (SS) values so that the ozone reaction is primarily for color removal. Wastewater is Ozonated after it exists from chemical or/and biological pretreatment at a dosage from 50 mg/lit to 150 mg/lit. At these levels, color can be reduced by 90 to 98%. The dosage simultaneously reduces chemical oxygen demand (COD) by about 45%. (Small increases of BOD, 5 to 9%, may occur.)

OZONE IN DISINFECTION IN FOOD PROCESSING UNIT

In most of the cases the stalling of any Food product is due to the growth of Bacteria and viruses, if we reduce the same with the help of some means we can increase its shelf life. But it is also equally important that the additive should be such which does not leave any residue in the final product and thus we are only left with one chemical that is OZONE. Ozone is a Triatomic state of oxygen and after disinfection and sterilization it converts back to Oxygen without leaving any residue. In your case we can use Ozone in following ways:

Environmental Air Sterilization System The air inside the packing and processing hall can be made disinfected with the help of diffusing Ozone into the Packing or processing hall we can make area completely sterilized without use of any fumigants or chemicals. Direct Treatment of Product Ozone can be bubbled or can be recirculated along with the product into the tank for reducing bacterial count. However, direct contact of product is a critical application and is to be carried out at most care. In case the Ozone contact is higher than the recommended limits, certain chemical changes contents may take place, which are undesirable. However, we can suggest you an appropriate system only after series of tests at your works. The water used for Processing can be made total disinfected. The water is used in number for applications in a food processing company, which includes washing of fruits and vegetables, meat products, fisheries, prawn and other products, cleaning the places adding to products and mixing into the process. The application of water can make the product highly infected in case the water is not disinfected or sterilized as per the standards. We have water treatment sterilization and equipment for production of ultra pure water for food processing applications. With the help of Ozonized Showers the containers and machines can be cleaned.

SEWAGE TREATMENT PLANT Air Purification & Odour Control By Ozone At Sewage

Ozone treatment for deodorization of odiferous gases has been acknowledged as a technically effective method for many years. During the past twenty-five years, hundreds of ozone installations for the treatment of sewage plant odors have been erected. Ozone is one of the strongest oxidants known and quickly breaks down odors compounds.

In the elimination of obnoxious odors', Ozone reacts with malodorous substances to produce oxidized products having better olfactory characteristics. Ozone has been found to be very effective on many contaminants including sulfides, mercaptans, amines, phenols, and similar chemical compounds. In addition, ozone is a very powerful germicide and destroys most airborne bacteria.

Typical Ozone Dosages

In the treatment of sewage plant odors, ozone requirements are well established and experimental work is usually not necessary. An ozone dosage in the range of one to two ppm by volume is usually adequate to deodorize exhaust gases from standard, covered, sewage treatment plants. Other applications have varying ozone requirements, since odors usually differ both qualitatively and quantitatively. Table 1 suggests general ozone dosages for various applications. This is based on an air change in the collection chamber once every five minutes and a contact time of thirty seconds.

Limit Of Ozone Concentration

Ozone Concentration should not exceed more than 0.1 PPM where persons are present, for eight hours or more per work day, and no person be exposed to a ceiling concentration of Ozone in excess of 0.6 mg/m³ (0.3 PPM by volume) for more than ten minutes. This limit is set as per OSHA standards. Safety information regarding product is contained in its Material Safety Data Sheet provided along with the system when supplied. When properly applied for odor control resulting residual ozone concentrations will be negligible. They will be below the Maximum Allowable Concentration (MAC) established for most jurisdictions as the maximum level to which an individual may be continuously exposed during an eight hour working day. Ozone destruction is achieved through the oxidation of odor producing compounds prior to release to the atmosphere with a controlled system.

STERILIZATION OF PROCESS AREA AND DAIRY PRODUCTS

Most of the diseases are WATER BORN and thus the use of DISINFECTED PROCESS WATER (water used in different processes) is increasing in dairies for the following stages.

Mixing : Water used for mixing in milk should be free from any microbiological contamination for more shelf life.

Cleaning and washing : Water used in cleaning of utensils and other devices which comes in direct contact with the product can contaminate the product if not washed with sterilized water.

CIP(clean in process) : The conventional methods like alkaline/acid cleaning with hot water disinfection or alkaline cleaning with acid chemical disinfection include risk of its remaining at the joints inside the pipeline and when milk is passed through the pipeline it gets mixed with it and this degrading its quality. Ozone is 10 times more powerful in killing bacteria than chlorine.

Methods To Overcome Contamination Problems In Dairies

Ozone is the most advanced and safe method of sterilization in any of the food products manufacturing unit. The disinfection of process water through ozonation after normal water treatment by filtration and RO technique is a proven technology today. Dairy water treatment system is considered incomplete without incorporation of ozonation system. Ozone drastically reduces the level of bacterial contamination including virus and pathogens or TPC(total plate count)and thus the product quality is enhanced substantially. Ozone is 10 times more powerful in killing bacteria than chlorine.